roof roll forming machine only in the world

- 15128741111

- haryyang@yeah.net

This type of roof sheet has advantage including beautiful, classical appearance and grace taste. It can be widely used in villadom, hotel, exhibition, vocation village, family construction and outdoor decorate.

corrugated sheet profile drawing:

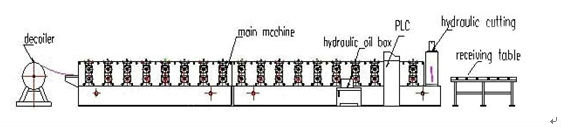

1.Manual decoiler_Roll forming machine_PLC system_Hydraulic system_Mold pressing-Post cut_Stacking

2. Technique parameters of the processing line

(1) Suitable material: Colored armor plate

(2) Thickness of the plate: 0.3-0.8mm

(3) Input width of the plate: Both decks is 1000mm

(4) Output width of first deck: 900mm

(5) Output width of second deck: 840mm

(6) Productivity: 12m/min

(7) Roller steps: 11 rows

(8) Roller material: 45# steel

(9) Diameter of active shaft: 70mm

(10) Wall thickness of the main forming machine: 12mm steel plate

(11) Main forming machine body: 300mmH steel

(12) Transmission chain is25.4mm, Reducer is 5.5kw Xingxing Cycloid which works stably and no noise.

(13) Cutting hydraulic system adapts CDF-10 gear pump, the motor power is 4kw, no noise, work stably, long life expectancy.

(14) PLC control system, easy to operate, high precision and work stably.

(15) Dimensions of major structure: 6200mm*1650mm*1510mm

3. Corrugated Roof panel forming machine Components of line:

|

De-coiler /Passive Uncoiler |

1 set |

|

Guiding Equipment /sheet guiding equipment |

1 set |

|

Forming machine/ Roll Forming Equipment /roll forming system |

1 set |

|

Pressing die |

1 set |

|

Cutting device /Post Cut Equipment |

1 set |

|

PLC control box/ PLC Control Penal /electric controlling system |

1 set |

|

Hydraulic pump station /Hydraulic Station |

1 set |

|

Production support table /Supporter Table /run out table /safety cover |

2 set |

4. Corrugated roof panel forming machine each part Technical Specification

(1) Manual decoiler

Un-powered; Single head;

Max. Capacity: 5000kg;

Coil inner-diameter: 508mm

(2) Roll-Forming M/C:

Steps: 11 Roller Material: 45# steel

Voltage: 380V/50Hz. Line speed: 12m/min;

Rolling chromium thickness: 0.05 mm

(3) Cutting Mechanism

It adopts hydraulic drive and automatic location to decide the dimention and cut the target products.

Match equipment: One set of cutting tool, one hydraulic tank, one cutter machine.

Stop to cut, Post cut cutting length tolerance: ± 2mm

Cutting tool material: GCr12 with quenched treatment 60-62° C

(4) Hydraulic System

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank, the pump drive the cutter machine to begin the cutting job.

Match equipment: A set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes and two sets of electromagnetism valves.

Power of the oil pump: 3kw Hydraulic oil: 40#

(5) Computer control cabinet:

It adopts Taida PLC to control. The target piece length is adjustable and digit of it can be adjusted

Computed mode has two modes: Automatic and manual one.

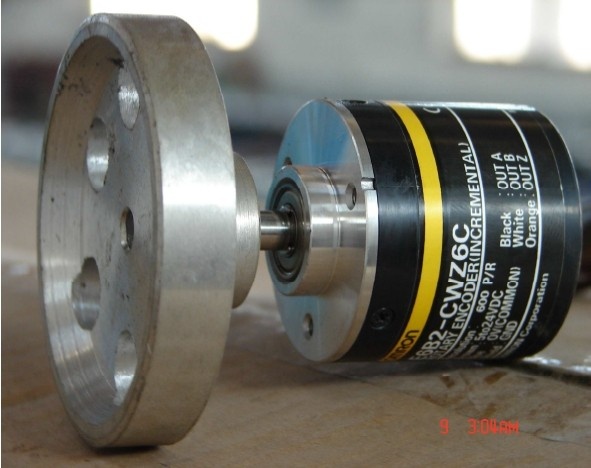

(6) Counter:

One counter gauges length, pulses, and decides length

(7) Output table

It used to load the forming plate