roof roll forming machine only in the world

- 15128741111

- [email protected]

JCX 1025/1116 Double Layers Roll Forming Machine

This kind of machine make two type of tile together perfectly, it has reasinable structure, beautiful appearance, with advantage of saving space, easy operate and especially welcomed by the costomers from home and abroad.

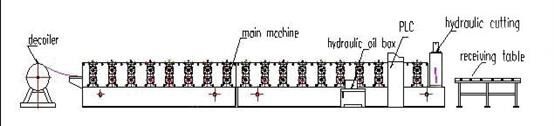

This machine is composed of feed leading table, main forming machine, cutting device, hydraulic station, computer control system and so on.

The shift of the up-layer and down-layer is easy completed by changing the button on the control box and the clutch to guide the power.

The model of the each sheet can be designed according to customers’ request.

1. Description of Equipment technical parameters

Weight: 5T

Rollers: 10-15 rows

Pressure: 10-12mpa

Drive type: By chain

Warranty: 12 months

Pump Station: 5.5 kw

Certification: CE/ISO9001

Width of the plate: 1200mm

Color: at the buyer’s option

Diameter of the rollers: 75mm

Prouction Capacity: 8-10 m/min

Material of the cutting blade: Cr12

Main power: 5.5kw with Cycloidal reducer

Dimension(L.W.H): 11000x1900x1600(mm)

Raw Material thickness: 0.3-0.8mm/0.2-0.8 mm

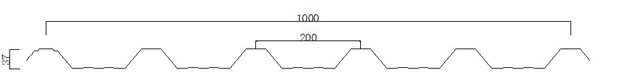

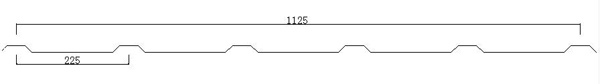

Effect width: according to client’s requirement

Machine frame stand: Welding structure frame

Application: Making steel roof, wall and ceiling

Voltage: 380V-3PH -50HZ (or as your requirement)

Host big frame structure: Frame welded 300H steel

Control system: PLC computer control -DETLA

Roller materials: 45 steel heated and quenched HRC 45-50

Raw material: color steel or galvanized steel/ 45forged steel, with surface polished and coated with 0.05mm thickness hard chrome

2. Working Processes

Man-made uncoiler—Roll forming machine—PLC system—Hydraulic system-Blade—Receiving table

3. Profile

4. Machine components

|

Passive Uncoiler |

1 set |

|

Guiding Equipment |

1 set |

|

Roll Forming Equipment |

1 set |

|

Pressing die |

1 set |

|

Post Cut Equipment |

1 set |

|

PLC control box |

1 set |

|

Hydraulic pump station |

1 set |

|

Production support table |

1 set |

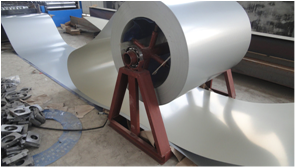

(1) Automatic decoiler (max capacity 5000kg)

(2) Main Machine -Roll-Forming M/C

(3) Cutting Mechanism

It adopts hydraulic drive and automatic location to decide the dimention and cut the target products.

Match equipment : one set of cutting tool, one hydraulic tank ,one cutter machine.

Cutting tool material: GCr12 with quenched treatment 60-62°C

(4)Computer control cabinet :

It adopts PLC to control. The target piece length is adjustable and digit of it can be adjusted.

Computed mode has two modes: automatic and manual one.

(5) Hydraulic System

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job.

Match equipment: a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes and two sets of electromagnetism valves.

Power of the oil pump: 3kw Hydraulic oil :40#

5. Applications

Our cold roll forming machine is uesd to produce any kinds of plate for the roof, wall, floor and other frame of building like workshop, warehouse and other house coating.

6. Advantages

We are a manufacturer, specialied in all kinds of roll forming machine.

15 years of experience for manufacturing and exportation.

Customers Design, Size, Color and Logo are accepted.

Elegant apparene good quality, compotitive price,

Simple control, good after-service and Prompt Delivery.

Main markets: Middle East, Europe, North America, Africa and Southeast Asia.

7. Packaging Detail

1. Main roof sheet roll forming machines is covered by plastic film.

2. PLC computer control box, spare parts and other small parts are packed by wooden carton box.